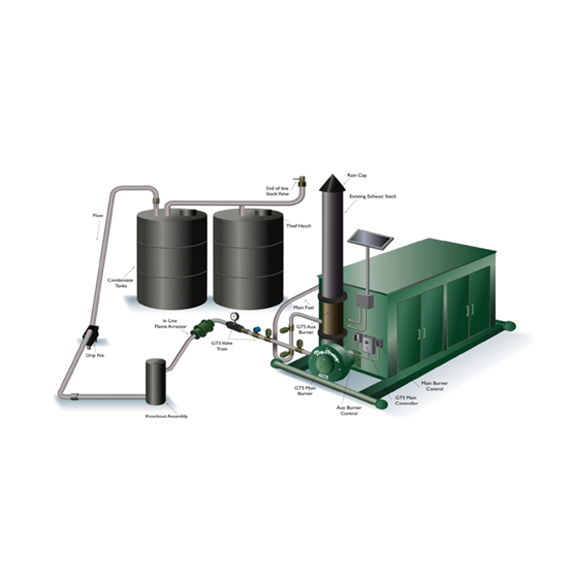

SlipStream® GTS is a patent pending technology designed to capture low pressure, highly variable vented hydrocarbons from oil and condensate storage tanks.

The GTS system routes vented gas to a main process burner or an auxiliary burner resulting in fuel savings, GHG reduction, and greater than 99.9% VOC destruction for environmental compliance. SlipStream® meets Federal, State and Provincial compliance regulations such as EPA NSPS subpart OOOO and Pennsylvania (PA) exemption 38 regulations.